Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

This article, CTT Technology's experts will help you understand both methods, compare their pros and cons, and decide which is better for your project based on cost, volume, and precision.

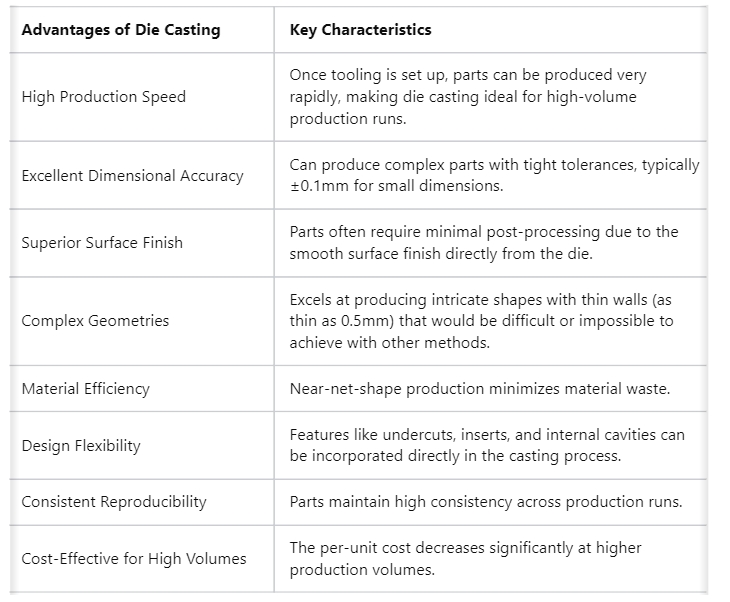

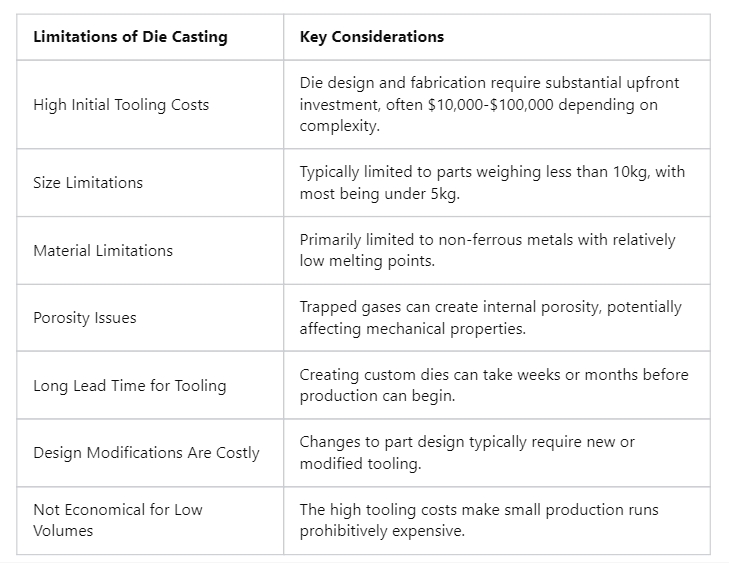

Die casting is a metal casting process where molten metal, typically non-ferrous alloys like aluminum, zinc, or magnesium, is injected into a steel mold under high pressure. The process includes various types, such as cold-chamber die casting, suitable for metals with high melting points like aluminum, and hot-chamber die casting, optimized for high-volume production with faster cycle times.

The die casting process involves several steps: mold preparation, metal injection, cooling and solidification, ejection and finishing, enabling the creation of intricate geometries with high dimensional accuracy. It is widely used in automotive for engine parts, aerospace for housings, and electronics for heat sinks and enclosures. Materials like magnesium alloys offer lightweight strength, making them ideal for thin-walled features, while zinc is cost-effective for applications where strength is less critical, such as toys.

1. Mold Preparation: The two halves of the steel die are clamped together and treated with lubricant.

2. Metal Injection: Molten metal (typically non-ferrous alloys like aluminum, zinc, magnesium, or copper) is injected into the die cavity under high pressure (1,000 to 20,000 psi).

3. Cooling and Solidification: The metal solidifies rapidly due to the cooler temperature of the die.

4. Ejection: The die opens and ejector pins push the solidified part out of the cavity.

5. Finishing: Parts may undergo finishing processes like trimming, machining, or surface treatment.

Die casting is typically categorized into two main types:

● Hot-chamber die casting: Used for low melting point metals like zinc, tin, and lead

● Cold-chamber die casting: Used for aluminum, magnesium, and copper alloys

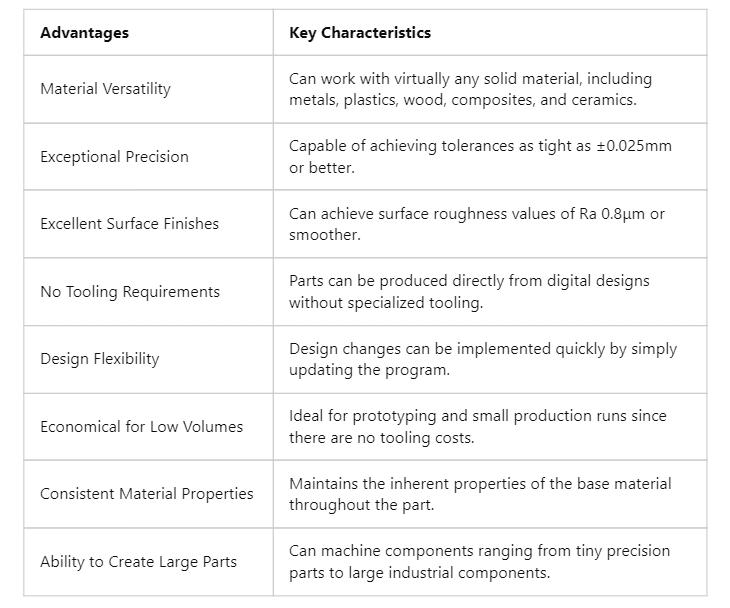

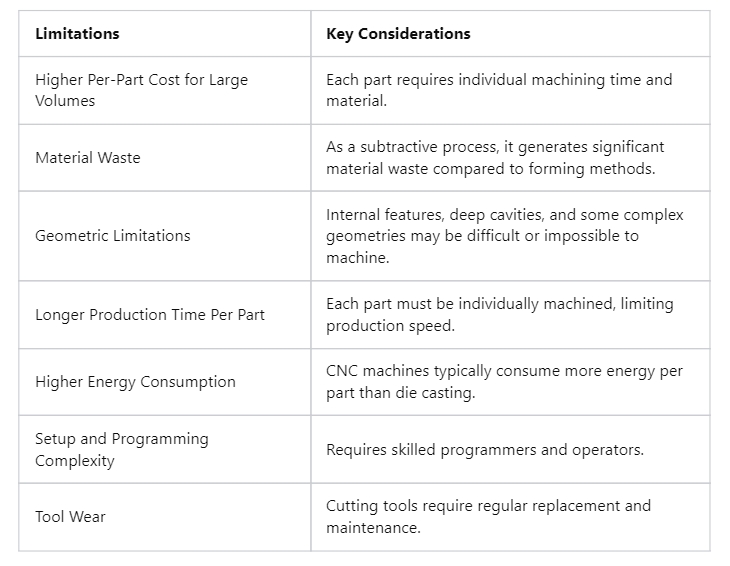

CNC machining, or Computer Numerical Control machining, is a subtractive manufacturing process that uses computer-controlled tools to remove material from a workpiece, creating precise parts. It encompasses processes like milling and turning, suitable for a wide range of materials, including metals like aluminum 6061, titanium Ti-6Al-4V, and plastics like ABS and PEEK. The process involves design and CAD modeling using software like AutoCAD, CAM programming for G&M codes, machine setup with tools like end mills, machining with set parameters, and post-processing for finishing, such as sandblasting or electroplating. It achieves tolerances as low as ±0.001 inches (±0.025 mm), making it ideal for prototypes and complex geometries in aerospace (turbine blades), medical (surgical instruments), and automotive (custom brackets).

Materials, as listed, include over 50 options, with metals like stainless steel 304, brass C360, and plastics like polycarbonate, offering versatility for various applications. Applications include aircraft structural components, medical implants, and electronics enclosures, showcasing its flexibility for industries requiring high precision.

1. Design Creation: A 3D CAD model of the part is created.

2. CAM Processing: Computer-Aided Manufacturing (CAM) software converts the design into a toolpath and generates G-code.

3. Machine Setup: The workpiece is mounted and tooling is installed in the CNC machine.

4. Machining Operations: The machine executes the programmed operations, which may include:Milling (removing material using rotating cutters)

a. Turning (rotating the workpiece against a cutting tool)

b. Drilling (creating holes)

c. Boring (enlarging existing holes)

d. Threading (creating internal or external threads)

5. Finishing: Parts may undergo deburring, surface treatments, or additional operations.

CNC machining can be performed on a variety of machine types, including mills, lathes, routers, grinders, and multi-axis machining centers.

Comparing die casting and CNC machining involves evaluating cost, volume, precision, and lead time. The following table summarizes key differences:

|

Aspect |

Die Casting |

CNC Machining |

|

Cost |

Cost-effective for large volumes; high initial mold cost. |

High initial costs; more expensive for complex geometries, offsets die cost for prototyping. |

|

Volume |

Economical for tens of thousands of identical parts. |

Suitable for medium to high runs (hundreds to thousands). |

|

Precision |

Excellent for accurate, repeatable parts; limited by metal alloy malleability. |

Ideal for highly accurate parts with tight tolerances, good for prototypes. |

|

Lead Time |

Requires upfront time for die creation; large changes need new molds. |

Faster for prototyping; allows modeling, testing, remodeling without new molds. |

|

Waste |

Produces less waste; material poured directly into mold. |

Tends to yield more scrap; material often cannot be repurposed. |

|

Applications |

Car parts, toys, gears, marine applications. |

Propeller engines, surgical equipment, electronics enclosures. |

Cost-wise, die casting is cheaper per part for very large volumes, while CNC machining is better for prototypes due to lower initial setup costs. Volume considerations show die casting excels at tens of thousands, while CNC machining suits hundreds to thousands. Precision is high for both, but CNC machining achieves tighter tolerances, making it ideal for niche, complex parts. Lead time favors CNC for prototyping, as die casting requires mold creation, which can delay large design changes.

Choose die casting for high-volume metal parts where repeatability is key, such as automotive components. Opt for CNC machining for low-volume, high-precision needs, like medical implants, where flexibility and design changes are crucial. An unexpected detail is that die casting’s lower waste production might appeal to environmentally conscious manufacturers, while CNC machining’s scrap could be a concern.

Yes, secondary operations like CNC machining are commonly performed on die cast parts to achieve tighter tolerances or create features that cannot be cast.

Depending on the material and complexity, a well-maintained die can typically produce 100,000 to over 1 million parts before requiring replacement.

No, CNC machining is inherently slower as each part must be individually machined. Die casting can produce parts in seconds once tooling is set up.

Die casting typically generates less material waste and can be more energy-efficient per part at scale. However, CNC machining allows easier material recycling and doesn't require the chemical release agents used in die casting.

CNC machining can process virtually any steel grade. Die casting is generally limited to non-ferrous metals, though specialized investment casting processes can work with steel.

CNC machining is typically preferred for prototyping due to faster turnaround times and lower setup costs. It also allows for iterative design changes without expensive tooling modifications.

As the core solution for modern manufacturing, the precision flexible intelligent manufacturing platform integrates precision processing, flexible production and intelligent management. This article analyzes its core value from its definition, hardware and software composition, and three core features of intelligence, flexibility and accelerated mass production, helping enterprises understand its role in industrial transformation.

Against the backdrop of manufacturing transformation, the precision flexible intelligent manufacturing platform has become a core support in high-end fields. This article details its definition, pain point solutions, and industry applications, helping enterprises understand the platform's value.

In the manufacturing of life science components and medical equipment parts, welding is a key factor in quality. Traditional manual welding struggles to meet high-precision requirements, and robotic arm welding, with its automation advantages, has become a core solution in the industry.

Precision planing and slotting use digital control to improve accuracy and consistency, and are widely used in medical and life science manufacturing.

Email to this supplier

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.