Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

To understand how to choose between CNC drilling and milling, it's crucial to first differentiate between these two fundamental machining processes. While both are subtractive manufacturing techniques utilizing computer numerical control (CNC) machines to remove material from a workpiece, they operate on different principles and are suited for distinct applications.

CNC drilling is primarily a hole-making process. It utilizes a rotating drill bit to create cylindrical holes in a workpiece. The mechanics of CNC drilling are relatively straightforward:

● Material Removal Mechanism: Drilling employs axial forces to shear material along the drill bit's path. The drill bit, characterized by its pointed end and flutes, penetrates the workpiece, and the flutes facilitate chip evacuation.

● Motion: The motion in drilling is predominantly linear. The drill bit moves along the Z-axis of the CNC machine, perpendicular to the workpiece surface, to create a straight, cylindrical hole.

● Tooling: Drilling tools are drill bits, available in various sizes and materials, optimized for creating holes of specific diameters and depths.

● Material Removal Rate (MRR): Drilling generally has a lower Material Removal Rate (MRR) compared to milling. This is because drilling is essentially a single-point cutting operation with limited workpiece engagement.

● Precision and Surface Finish: Drilling excels in producing holes with high accuracy in diameter and depth. The surface finish within a drilled hole is typically functional but may not be as smooth as surfaces achieved by milling.

● Versatility: Drilling is specialized for creating holes. Its versatility is limited to hole-making operations, such as through holes, blind holes, and tapped holes.

● CNC Control: CNC drilling machines precisely control the drill bit's position, feed rate, and spindle speed to ensure accurate hole dimensions and placement.

CNC milling is a more versatile machining process used to create a wide range of shapes and features beyond just holes. It employs a rotating milling cutter to remove material from a workpiece. Key aspects of CNC milling include:

● Material Removal Mechanism: Milling involves a complex cutting action where the milling cutter, equipped with multiple cutting edges, engages the workpiece at multiple points simultaneously. This allows for material removal in various directions and shapes.

● Motion: Milling involves simultaneous rotational and linear movements of the milling cutter relative to the workpiece. CNC milling machines operate across multiple axes (X, Y, and Z, and often additional axes for more complex geometries), enabling cutting along different axes and directions.

● Tooling: Milling utilizes a diverse array of milling cutters, such as end mills, ball nose cutters, face mills, and more. Each cutter type is designed for specific operations like slot cutting, face milling, contouring, and surface finishing.

● Material Removal Rate (MRR): Milling can achieve higher MRRs compared to drilling, especially for surface removal and shaping operations. The multi-point cutting action and ability to use larger cutters contribute to this higher MRR.

● Precision and Surface Finish: Milling offers greater flexibility and precision in shaping workpieces. It can achieve tighter tolerances and smoother surface finishes compared to drilling, particularly on external surfaces and complex contours.

● Versatility: CNC milling is highly versatile, capable of producing a wide range of features and geometries, including:

○ Flat Surfaces: Face milling creates smooth, flat surfaces on large workpieces.

○ Slots and Pockets: End milling and slot milling are used to create grooves, channels, and cavities.

○ Complex 3D Shapes: Contour milling and profile milling enable the creation of intricate 3D surfaces and complex geometries.

○ Gears and Threads: Specialized milling operations can produce gears and threads.

○ Intricate Contours: 5-axis milling machines can create highly complex and contoured parts.

● CNC Control: CNC milling machines provide precise control over the cutter's position, feed rate, spindle speed, and depth of cut, allowing for intricate and accurate shaping of workpieces.

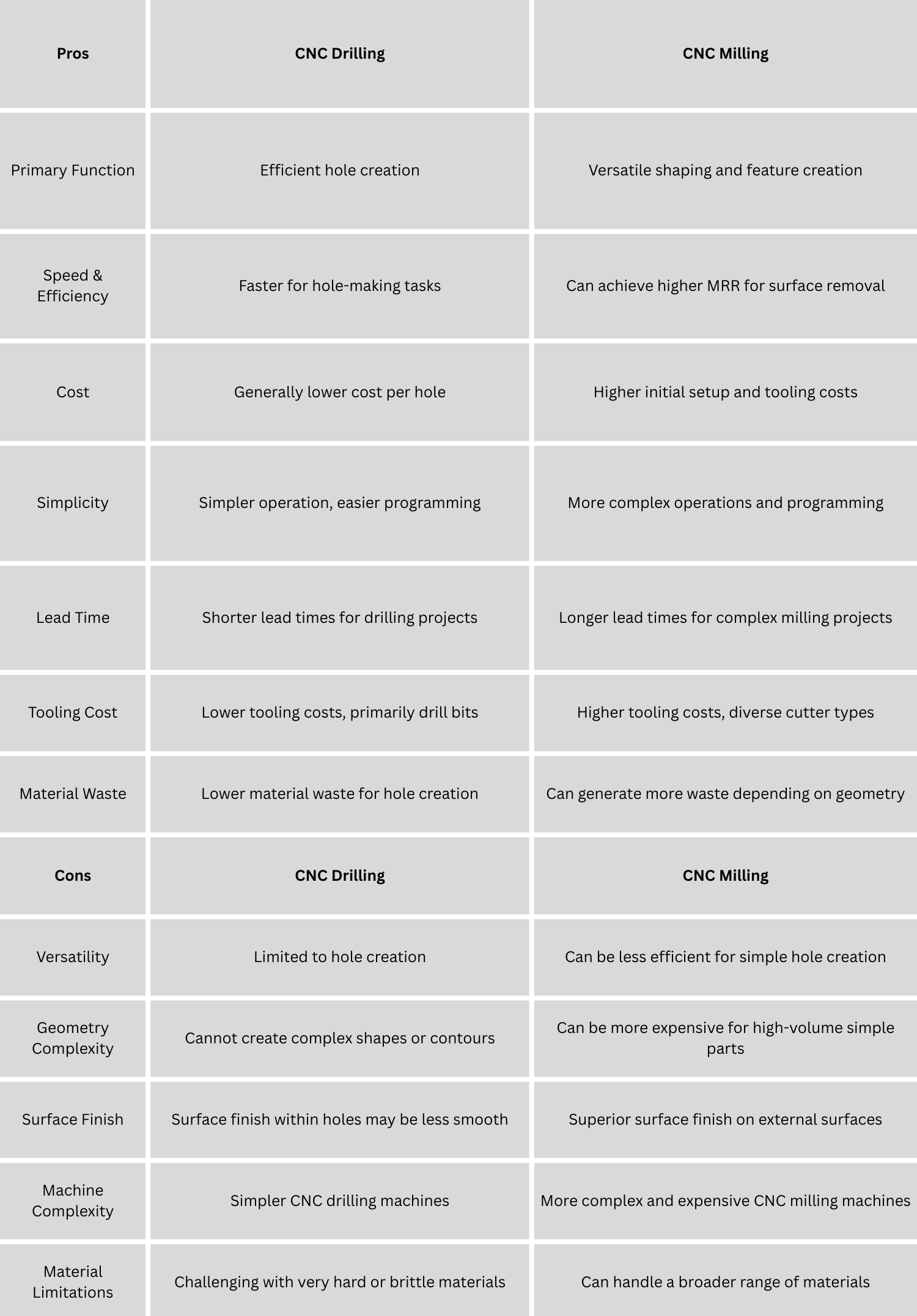

Both CNC drilling and milling offer distinct advantages and disadvantages depending on the specific manufacturing requirements. Understanding these pros and cons is crucial for selecting the appropriate process.

This table summarizes the key trade-offs between CNC drilling and milling, highlighting that the "best" choice depends heavily on the specific application and desired outcomes.

Choosing between CNC drilling and milling is not a one-size-fits-all decision. It depends on several critical factors related to the workpiece, desired features, production requirements, and available resources. Let's address the key follow-up questions to guide this selection process:

1. Material of workpiece?

The material of the workpiece significantly influences the choice between drilling and milling, as well as the specific parameters and tooling required for each process.

a. Aluminum Alloys: Aluminum is generally easier to machine with both drilling and milling due to its good machinability.

i. Drilling: Aluminum drills efficiently and cleanly. High-speed steel (HSS) or carbide drills are suitable. Coolant is recommended to prevent chip buildup.

ii. Milling: Aluminum mills exceptionally well. High cutting speeds and moderate feed rates are beneficial. Carbide end mills are preferred. Coatings with low affinity to aluminum, like zirconium-based coatings, prevent buildup on the cutting edge. Coolant is essential.

b. Steel Alloys: Steel, especially stainless steel, presents more machining challenges due to its toughness and work-hardening properties.

i. Drilling: Drilling steel requires more robust tooling and slower speeds compared to aluminum. Cobalt HSS or carbide drills are recommended. Effective cooling and lubrication are crucial to manage heat and chip evacuation.

ii. Milling: Milling steel demands rigid setups, slower cutting speeds, and appropriate tooling. Carbide end mills with coatings like TiN, TiCN, or AlTiN are suitable for steel. High-performance coatings like Ti Nano and HXC-Nano 4 are recommended for hardened and stainless steels.

c. Titanium Alloys (Ti-6Al-4V): Titanium is notoriously difficult to machine due to its high strength, low thermal conductivity, and tendency to work harden.

i. Drilling: Drilling titanium requires very low cutting speeds, sharp carbide drills with coatings like TiAlN or TiCN, and high-pressure coolant. Rigid setups are essential to minimize vibration.

ii. Milling: Milling titanium is also challenging and requires even lower cutting speeds than drilling. Sharp carbide end mills with coatings optimized for titanium (e.g., TiAlN, TiCN, Ti Nano, HXC-Nano 4) are necessary. High-pressure coolant is critical to dissipate heat and lubricate the cutting zone. Rigid machine and workpiece fixturing are paramount.

2. Feature type to be created?

The type of feature to be created is a primary determinant in choosing between CNC drilling and milling.

a. Holes: If the primary requirement is to create holes, CNC drilling is the clear choice. It is specifically designed and optimized for efficient and precise hole making. Drilling is faster and more cost-effective for producing cylindrical holes compared to milling.

b. Slots, Pockets, and Grooves: For creating slots, pockets, grooves, and keyways, CNC milling is the preferred process. Techniques like slot milling, plunge milling, and circular interpolation milling are specifically designed for these features. While drilling can initiate a hole for a pocket, milling is essential for shaping the pocket's geometry.

c. Complex 3D Shapes and Contours: CNC milling is indispensable for creating complex 3D shapes, contoured surfaces, and intricate geometries. Profile milling, contour milling, and 5-axis milling are used to achieve these features. Drilling is not capable of creating such shapes.

d. Flat Surfaces: Face milling, a type of CNC milling, is used to create flat surfaces on large workpieces. Drilling is not relevant for creating flat surfaces.

e. Chamfers and Edges: Chamfer milling is a specific milling operation designed to create smooth, curved edges and chamfers. Drilling does not offer this capability.

f. Threads: While drilling can create a pilot hole for threading, thread milling is a milling process used to create threads, especially for larger or more precise threads. Tapping is often used after drilling for internal threads, but milling offers an alternative for certain thread types.

3. Required tolerance and surface finish?

The required tolerance and surface finish are critical factors influencing the choice between CNC drilling and milling, as well as the specific machining parameters and post-processing steps.

a. Tolerance:

i. Drilling: CNC drilling can achieve high diametrical and positional tolerances for holes, typically within ±0.001" to ±0.005" (±0.025mm to ±0.127mm), depending on machine precision, tooling, and material.

ii. Milling: CNC milling can achieve even tighter tolerances, often down to ±0.0005" (±0.0127mm) or better, especially with precision milling machines and skilled operators. Milling offers greater control over dimensional accuracy for complex shapes and features.

b. Surface Finish:

i. Drilling: The surface finish inside a drilled hole is typically functional, with Ra values ranging from 3.2 μm to 6.3 μm. It may exhibit feed marks and be less smooth than milled surfaces.

ii. Milling: CNC milling can achieve superior surface finishes compared to drilling. Depending on cutting parameters, tooling, and number of passes, milling can achieve Ra values from 0.8 μm to 3.2 μm or even finer (e.g., 0.4 μm with finishing passes). Techniques like high-speed milling and finishing passes are used to improve surface finish. Grinding can achieve even finer finishes (Ra 0.1µm – 1.5μm) if required.

c. Surface Roughness and Applications:

i. 3.2 μm Ra: Standard commercially available CNC machining surface roughness, suitable for general-purpose parts under stress.

ii. 1.6 μm Ra: Ideal for slow-moving surfaces with light loads (e.g., hydraulic piston rods, precision fasteners). Achieved with higher machining speeds and slower feeds, increasing cost.

iii. 0.8 μm Ra: Best for high-stress applications or surfaces with occasional motion (e.g., hydraulic valve components). Requires finishing passes, increasing cost.

iv. 0.4 μm Ra: Recommended for high-speed or high-stress components (e.g., pneumatic cylinder rods, optical components). Very high-grade smooth texture, significantly increasing cost.

If high tolerances and smooth surface finishes are critical, especially for external surfaces and complex geometries, CNC milling is the preferred choice. Drilling is sufficient for holes where functional surface finish and moderate tolerances are acceptable. Achieving very fine surface finishes (below Ra 0.8 μm) generally requires milling with finishing passes or additional processes like grinding or polishing, significantly increasing machining time and cost.

4. Production volume expected?

The expected production volume significantly impacts the cost-effectiveness and suitability of CNC drilling versus milling.

a. High Production Volume (Mass Production): For high-volume production of parts primarily requiring holes, CNC drilling is highly cost-effective. Drilling is a faster and simpler process for hole making, leading to lower per-part costs in large quantities. Automated CNC drilling machines can further enhance efficiency and reduce labor costs in mass production.

b. Low to Medium Production Volume: For low to medium production volumes, or when parts require a mix of holes and complex features, CNC milling becomes more versatile and potentially cost-effective overall. While milling may be slightly more expensive per operation than drilling, its ability to create a wider range of features in a single setup can reduce the total number of setups and machines required, especially for complex parts.

c. Prototyping and Small Batches: For prototyping and small batches, CNC milling is often preferred due to its flexibility and ability to quickly adapt to design changes. The setup cost for milling, while higher than drilling for simple holes, is justified by its versatility in creating various features needed in prototypes and small runs.

d. Cost Considerations:

i. Drilling Costs: Primarily influenced by drilling depth, hole diameter, and number of holes. Cost-effective for high-volume hole production.

ii. Milling Costs: Depend on part complexity, material, setup, machining time, and number of operations. Milling is generally more expensive per operation but offers greater feature integration.

iii. Economies of Scale: Larger production runs benefit from economies of scale for both drilling and milling, but drilling typically sees a more pronounced cost reduction per part in very high volumes due to its simplicity and speed.

5. Available CNC machine capabilities?

The capabilities of the available CNC machines are a crucial constraint in choosing between drilling and milling.

a. CNC Drilling Machines: Specialized CNC drilling machines are optimized for high-speed, high-volume hole production. They are typically simpler and less expensive than CNC milling machines. Their capabilities are primarily limited to drilling and related hole-making operations like tapping and reaming.

b. CNC Milling Machines (Machining Centers): CNC milling machines, also known as machining centers, are more versatile and capable of performing a wide range of operations, including milling, drilling, tapping, boring, and contouring. They come in various configurations (3-axis, 4-axis, 5-axis, horizontal, vertical) with different levels of complexity and precision.

c. Turning-Milling Centers (Compound Machines): These hybrid machines combine the capabilities of CNC lathes and CNC mills, allowing for turning, milling, and drilling operations in a single setup. They are ideal for complex parts requiring both rotational and prismatic features.

d. Machine Axis Configuration:

i. 3-axis Milling Machines: Suitable for basic milling and drilling operations on three axes (X, Y, Z).

ii. 4-axis and 5-axis Milling Machines: Necessary for complex 3D shapes, simultaneous multi-sided machining, and intricate contours.

iii. Horizontal vs. Vertical Machining Centers: Horizontal machining centers are often preferred for high-volume production and machining of larger parts, while vertical machining centers are more versatile for general-purpose milling and drilling.

e. Automatic Tool Changers (ATCs): CNC milling machines with ATCs enhance efficiency by allowing for automatic tool switching, enabling multiple operations (drilling, milling, tapping, etc.) in a single setup.

f. Machine Rigidity and Accuracy: The rigidity and accuracy of the CNC machine directly impact achievable tolerances and surface finish in both drilling and milling. High-precision machines are required for demanding applications.

If only CNC drilling machines are available, the manufacturing capabilities are limited to hole-centric parts. CNC milling machines offer broader capabilities, allowing for a wider range of features and part geometries. Turning-milling centers provide the most comprehensive capabilities for complex parts requiring both turning and milling operations. The choice of machine should align with the required part complexity, production volume, and budget. Investing in more versatile CNC milling machines or turning-milling centers can provide greater manufacturing flexibility and capability for diverse product requirements.

Choosing between CNC drilling and milling hinges on a careful evaluation of the specific manufacturing needs. CNC drilling excels in efficient and precise hole creation, offering speed and cost-effectiveness for high-volume hole production. It is the ideal choice when the primary requirement is to produce holes with good accuracy and functional surface finish.

CNC milling, on the other hand, provides unparalleled versatility in shaping materials. It is essential for creating complex geometries, contours, slots, pockets, and achieving superior surface finishes and tighter tolerances. While generally more complex and potentially more expensive per operation than drilling, milling's adaptability makes it indispensable for a wide range of manufacturing applications, especially for parts requiring intricate features and high precision.

For manufacturers, the decision often involves balancing cost, production volume, part complexity, and required quality. In many cases, a combination of both drilling and milling processes is employed to optimize manufacturing efficiency and achieve the desired part characteristics. Hybrid CNC machines and multi-tasking centers further blur the lines, offering integrated solutions that leverage the strengths of both drilling and milling within a single setup, representing a future trend towards more versatile and efficient manufacturing processes. Ultimately, a thorough understanding of the nuances of each process, coupled with a clear definition of manufacturing objectives, will guide the optimal choice between CNC drilling and milling.

A biological safety cabinet (BSC) provides essential protection for laboratory personnel, samples, and the environment when handling hazardous microorganisms. This article explains BSC functions, material requirements, manufacturing and safety standards, and key testing procedures. It also highlights the differences between biological safety cabinets and laminar flow hoods, helping users select the proper equipment for their laboratory. Through clear guidance on certification and maintenance, the article supports safer, more efficient laboratory operations.

Learn the importance of inkjet printer shell design, including material selection, structural requirements, manufacturing processes, maintenance methods, and solutions for common shell failures. Improve durability, stability, heat dissipation, and overall performance of industrial inkjet printers with expert guidance.

Medical sheet metal processing delivers precise, reliable components for surgical tools, diagnostic devices, and healthcare equipment, enhancing safety and performance.

This article analyzes the advantages of laser cutting technology in sheet metal welding processing, including high precision, rapid cutting, and reduced material waste. Through practical examples, it demonstrates the significant effects of laser cutting in improving production efficiency and reducing costs, and discusses future technological development trends.

Email to this supplier

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.