What is Grinding: A Comprehensive Overview

2025-04-10

Grinding, a critical subtractive manufacturing process, plays an indispensable role in modern industry. It is employed across diverse sectors to achieve precise dimensions, superior surface finishes, and exacting tolerances on a wide array of materials. This report provides a detailed exploration of grinding, encompassing its fundamental principles, operational mechanisms, material applications, process variations, common uses, advantages, disadvantages, and future trends.

What is Grinding?

Grinding is an abrasive machining process that utilizes a grinding wheel composed of hard abrasive particles to shape, finish, or cut a workpiece. Unlike conventional machining processes that employ single-point or multi-point cutting tools with defined geometries, grinding relies on a multitude of randomly oriented, extremely hard abrasive grains. These grains, much smaller and more numerous than milling cutter teeth, act as micro-cutting edges, removing minute amounts of material in the form of chips.

The primary objective of grinding is to achieve high precision and superior surface finish. It is particularly effective for materials that are difficult to machine using conventional methods, including hardened steels, ceramics, and composites. Grinding is a versatile process applicable to a broad spectrum of materials, ranging from soft metals to ultra-hard substances.

How Does Grinding Work?

The operational principle of grinding is rooted in the abrasive action of numerous hard particles against a workpiece. Several key aspects differentiate grinding from other machining processes like milling:

- Abrasive Grains: Grinding utilizes abrasive grains that are significantly smaller and more numerous than the cutting teeth found on milling cutters. These grains are typically made of materials like aluminum oxide (), silicon carbide (), cubic boron nitride (CBN), or diamond, depending on the workpiece material and desired outcome.

- High Cutting Speeds: Grinding processes typically involve significantly higher cutting speeds compared to milling. This high-speed interaction between the abrasive grains and the workpiece facilitates efficient material removal.

- Randomly Oriented Abrasive Grits: Unlike the precisely defined geometry of milling cutters, abrasive grits in a grinding wheel are randomly oriented. This randomness contributes to the self-sharpening action characteristic of grinding.

- Self-Sharpening Action: As grinding progresses, abrasive grains become dull due to wear. However, under grinding forces, these dull particles either fracture, exposing new sharp cutting edges (grain fracture), or are pulled out of the bonding material (bond fracture), revealing fresh, sharp grains. This self-sharpening mechanism maintains the cutting efficiency of the grinding wheel.

- Heat Generation: Grinding is inherently a thermally intensive process. A significant portion of the energy expended during grinding is converted into heat due to friction and plastic deformation at the cutting zone. Effective coolant application is crucial to manage this heat, preventing thermal damage to the workpiece, minimizing thermal distortion, and extending the life of the grinding wheel.

Grinding Wheel Composition:

A grinding wheel is a composite structure comprising two essential components:

- Abrasive Grains: These are the cutting elements of the grinding wheel. Common abrasive materials include:

- Aluminum Oxide: Suitable for grinding ferrous metals, alloy steels, and high-speed steels due to its toughness and cost-effectiveness.

- Silicon Carbide: Used for grinding non-ferrous metals, cast iron, and non-metallic materials like ceramics and glass. Silicon carbide is harder but more brittle than aluminum oxide.

- Cubic Boron Nitride (CBN): A superabrasive material exceptionally hard and heat-resistant, ideal for grinding hardened steels, tool steels, and superalloys. CBN wheels offer superior performance in demanding applications.

- Diamond: The hardest known material, diamond abrasives are used for grinding ultra-hard materials like cemented carbides, ceramics, glass, and composites. Diamond grinding wheels are essential for precision machining of extremely hard substances.

- Bonding Material: The bonding material holds the abrasive grains together, forming the shape and structure of the grinding wheel. Common bond types include:

- Vitrified Bond: Ceramic bonds offering high strength, rigidity, and resistance to heat and chemicals. Vitrified bonds are widely used for precision grinding applications.

- Resin Bond: Organic bonds providing more flexibility and shock resistance than vitrified bonds. Resin bonds are suitable for applications requiring good surface finish and vibration damping.

- Metal Bond: Metallic bonds offering exceptional strength and wear resistance, primarily used for diamond and CBN superabrasive wheels in demanding applications.

- Electroplated Bond: A single layer of abrasive grains is electroplated onto a metal substrate. Electroplated wheels offer aggressive cutting action and are form-holding, eliminating the need for frequent dressing.

Grinding Wheel Wear:

Grinding wheel wear is an inevitable phenomenon that affects the performance and lifespan of the wheel. The primary mechanisms of grinding wheel wear are:

- Grain Fracture: A portion of the abrasive grain breaks off due to cutting forces or thermal stress, exposing a new, sharper cutting edge. This is a desirable form of wear as it contributes to the self-sharpening action.

- Attritious Wear: The abrasive grains become dull or flattened at their cutting edges due to repeated contact and friction with the workpiece. This dulling reduces cutting efficiency and increases heat generation.

- Bond Fracture: The bonding material fractures, causing entire abrasive grains to be pulled out of the wheel. This type of wear reduces the number of active cutting points and necessitates wheel dressing or replacement.

What Materials Can Be Used in Grinding?

Grinding is exceptionally versatile in terms of the materials it can process. It is employed for machining a wide range of materials across various hardness and toughness spectra, including:

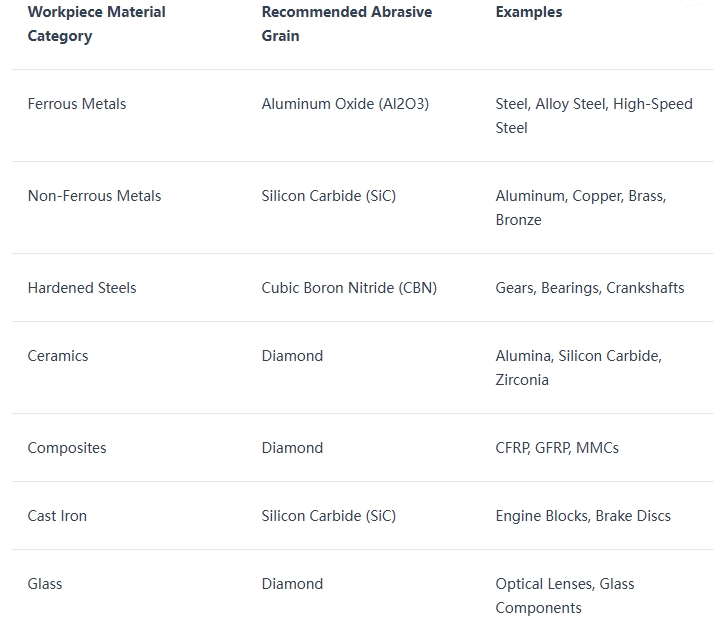

- Ferrous Metals: Steels (carbon steels, alloy steels, stainless steels, hardened steels, tool steels), cast iron. Aluminum oxide and CBN abrasives are commonly used for grinding ferrous materials.

- Non-Ferrous Metals: Aluminum, copper, brass, bronze, titanium, nickel alloys (Inconel). Silicon carbide and diamond abrasives are often preferred for non-ferrous metals.

- Hardened Steels: Grinding is particularly well-suited for machining hardened steels, which are challenging to cut with conventional methods. CBN and diamond wheels are essential for grinding hardened steel components in automotive and aerospace industries.

- Ceramics: Technical ceramics like alumina, silicon carbide, zirconia, and ceramic matrix composites (CMCs) are extremely hard and brittle, making grinding the primary machining method. Diamond grinding wheels are indispensable for ceramic machining.

- Composites: Fiber-reinforced polymers (CFRP, GFRP), metal matrix composites (MMCs). Grinding is used for trimming, shaping, and finishing composite components, often employing diamond abrasives to minimize fiber pull-out and delamination.

- Glass: Precision grinding with diamond wheels is used for shaping and finishing optical glass components and other glass products.

- Plastics and Polymers: Certain plastics and polymers can be ground, although other machining methods are often more efficient. Abrasive belt grinding and specialized grinding wheels can be used for specific plastic applications.

The selection of the appropriate abrasive grain material is crucial and depends primarily on the grindability of the workpiece material. Aluminum oxide is generally preferred for ferrous metals, while silicon carbide is better suited for non-metals and non-ferrous metals. For ultra-hard materials like hardened steels and ceramics, CBN and diamond abrasives are essential.

Abrasive Grain Selection Based on Workpiece Material:

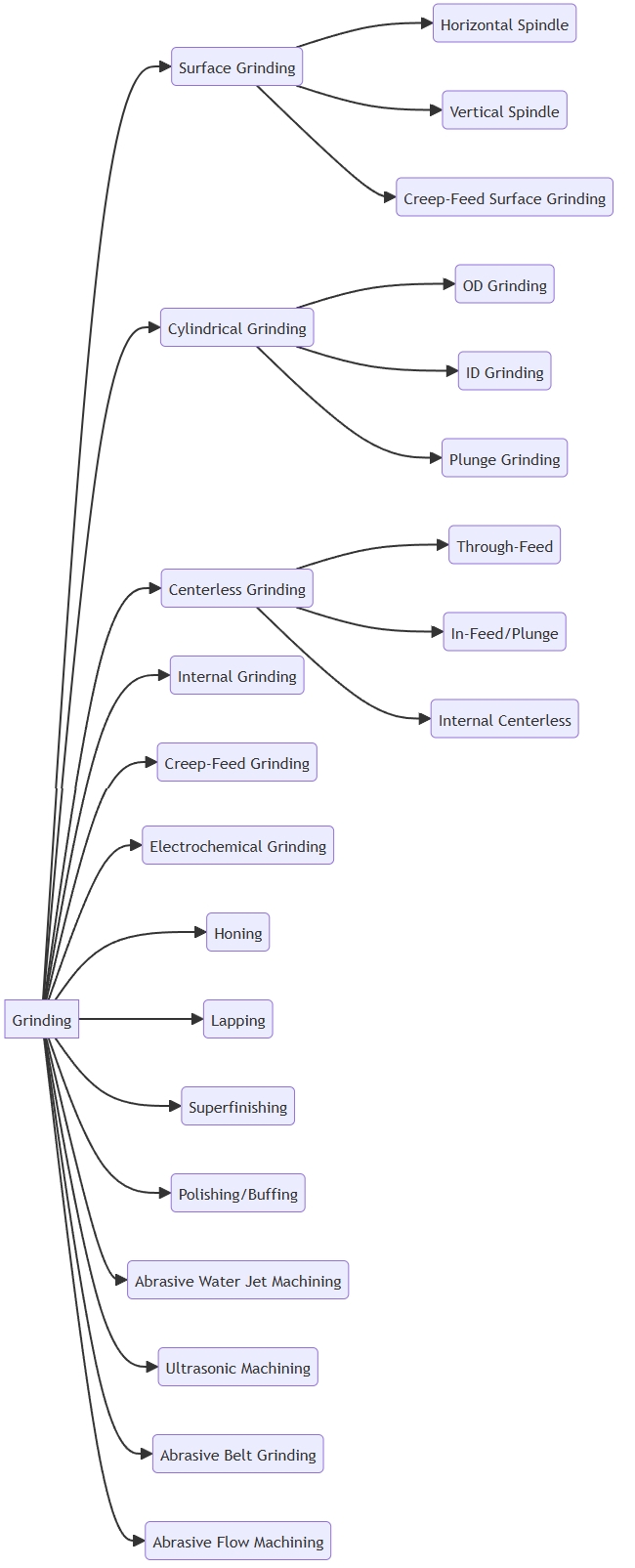

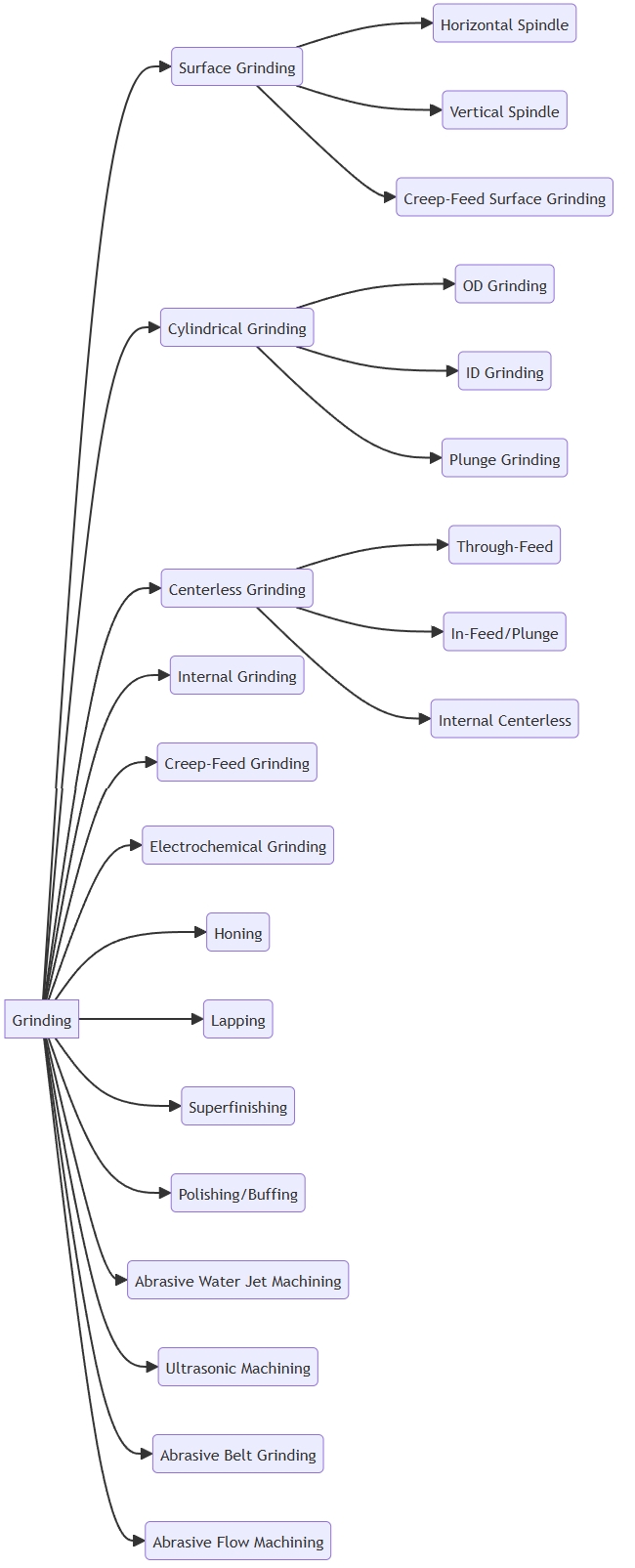

What Are the Different Types of Grinding?

Grinding encompasses a diverse range of processes, each tailored to specific applications and workpiece geometries. The major types of grinding processes include:

- Surface Grinding: Used to produce flat surfaces with high precision and fine surface finish. Surface grinding machines typically employ a horizontal or vertical spindle and a reciprocating table to move the workpiece under the grinding wheel. Subtypes include:

- Horizontal Spindle Reciprocating Table Surface Grinding: Common for general-purpose surface grinding.

- Vertical Spindle Rotary Table Surface Grinding: Suitable for grinding large flat surfaces.

- Creep-Feed Grinding (CFG): A high material removal rate process using a deep depth of cut and slow feed rate. CFG is effective for producing complex profiles and is widely used in aerospace and turbine industries.

- Cylindrical Grinding: Used to grind cylindrical surfaces, both external (OD) and internal (ID). Cylindrical grinding machines rotate the workpiece and the grinding wheel synchronously. Types of cylindrical grinding include:

- Outside Diameter (OD) Grinding: For grinding external cylindrical surfaces, shafts, and pins.

- Inside Diameter (ID) Grinding: For grinding internal bores and holes. Internal grinding often uses smaller grinding wheels at higher speeds.

- Centerless Grinding: The workpiece is supported on a work blade and rotated by a regulating wheel, eliminating the need for centers or chucks. Centerless grinding is highly efficient for high-volume production of cylindrical components. Subtypes include through-feed, in-feed/plunge, and internal centerless grinding.

- Plunge Grinding: The grinding wheel is fed directly into the workpiece to create a specific form or diameter.

- Honing: A low-speed abrasive process used to improve the surface finish and dimensional accuracy of internal bores and cylindrical surfaces. Honing employs abrasive stones or hones to remove minute amounts of material, resulting in precise dimensions and excellent surface finish. Honing is commonly used for cylinder bores in engines and hydraulic components.

- Lapping: A precision abrasive process used to achieve extremely fine surface finishes and high dimensional accuracy. Lapping involves rubbing a workpiece against a lapping plate or tool with a fine abrasive slurry. Lapping is used for producing optical flats, valve seats, and gauge blocks.

- Superfinishing: An advanced abrasive process similar to honing but employing finer abrasives and lower pressures to achieve ultra-fine surface finishes, often in the nanometer range. Superfinishing is used for critical components requiring exceptional surface quality, such as bearings and sealing surfaces.

- Polishing and Buffing: Abrasive processes used to improve surface finish and reflectivity. Polishing typically uses abrasive compounds on rotating wheels or belts, while buffing uses softer wheels and finer compounds to achieve a mirror-like finish.

- Abrasive Water Jet Machining (AWJM): A non-traditional abrasive process that uses a high-pressure jet of water mixed with abrasive particles to cut or shape materials. AWJM is versatile and can cut a wide range of materials, including metals, composites, and ceramics, with minimal heat generation.

- Electrochemical Grinding (ECG): A hybrid process combining electrochemical machining and abrasive grinding. ECG uses an electrically conductive grinding wheel as a cathode and the workpiece as an anode in an electrolytic solution. Material removal is primarily through electrochemical dissolution, with the abrasive action of the wheel removing the passivated layer. ECG is particularly effective for machining hard and brittle materials with minimal wheel wear and heat generation.

- Ultrasonic Machining (USM): A non-traditional abrasive process that uses ultrasonic vibrations to drive abrasive particles against the workpiece, causing material erosion. USM is suitable for machining hard and brittle materials, including ceramics and glass, and can produce intricate shapes.

- Abrasive Belt Grinding: Uses abrasive belts instead of grinding wheels for material removal and surface finishing. Abrasive belt grinding is versatile and can be used for stock removal, deburring, and polishing of various materials.

- Abrasive Flow Machining (AFM): A specialized abrasive process that uses a viscous abrasive medium forced through or around a workpiece to achieve deburring, polishing, and edge radiusing of internal passages and complex geometries. AFM is particularly useful for finishing inaccessible areas.

Types of Grinding Processes:

What Are the Common Applications of Grinding?

Grinding is a ubiquitous manufacturing process with applications spanning across numerous industries. Its ability to achieve high precision, fine surface finishes, and tight tolerances makes it indispensable for critical components in various sectors:

- Automotive Industry: Grinding is essential for manufacturing critical automotive components such as:

- Crankshafts and Camshafts: Precision grinding ensures dimensional accuracy and surface finish for optimal engine performance and longevity. CBN grinding wheels are frequently used for high-volume crankshaft and camshaft production.

- Gears: Grinding is used to achieve the required gear tooth profiles, surface finish, and case hardness for transmission gears and other drivetrain components. Generating grinding with CBN grinding worms is increasingly used for gear flank modification in electric vehicle applications.

- Bearings: Grinding is crucial for producing bearing races and rollers with high roundness, surface finish, and dimensional accuracy, ensuring smooth and reliable bearing operation. Centerless grinding is widely used for bearing component manufacturing.

- Fuel Injection Components: Precision grinding is required for fuel injection nozzles and seats to achieve the tight tolerances necessary for efficient and precise fuel delivery.

- Aerospace Industry: The stringent requirements of the aerospace industry necessitate extensive use of grinding for manufacturing high-performance components:

- Turbine Blades and Vanes: Grinding is critical for achieving the complex aerodynamic profiles, surface finish, and dimensional accuracy of turbine blades and vanes made from heat-resistant superalloys (Inconel, titanium). Creep-feed grinding and electrochemical grinding are commonly employed.

- Landing Gear Components: Grinding ensures the high strength, fatigue resistance, and dimensional precision of landing gear struts, pins, and hydraulic cylinders. Cylindrical grinding and surface grinding are essential processes.

- Engine Shafts and Components: Precision grinding is used for manufacturing engine shafts, housings, and other critical components requiring high accuracy and surface integrity.

- Honeycomb Structures: Electrochemical grinding is particularly effective for machining intricate honeycomb structures used in aerospace for lightweighting and structural integrity.

- Medical Device Manufacturing: Grinding plays a vital role in producing medical implants and instruments requiring biocompatibility, precision, and fine surface finishes:

- Orthopedic Implants: Hip and knee implants, dental implants, and spinal implants require precision grinding to achieve the necessary fit, surface finish, and biocompatibility.

- Surgical Instruments: Grinding is used to sharpen surgical blades, needles, and other instruments, ensuring sharpness and precision.

- Tool and Die Making: Grinding is fundamental in tool and die manufacturing for creating molds, dies, and cutting tools with high precision and surface finish:

- Molds and Dies: Precision grinding is used to create intricate mold cavities and die profiles for plastic injection molding, die casting, and metal forming.

- Cutting Tools: Tool and cutter grinders are used to sharpen and recondition cutting tools like end mills, drills, and inserts, maintaining their cutting efficiency and extending their lifespan. Superabrasive grinding with diamond and CBN wheels is essential for tool and die manufacturing.

- Machinery Manufacturing: Grinding is used for producing precision components in various machinery applications:

- Hydraulic and Pneumatic Components: Grinding is used to manufacture hydraulic cylinders, valve spools, and pneumatic components requiring tight tolerances and smooth surfaces for leak-free operation. Honing and superfinishing are often employed.

- Precision Spindles and Shafts: Grinding ensures the high roundness, straightness, and surface finish of precision spindles and shafts used in machine tools and other high-precision equipment. Cylindrical grinding is the primary process.

- Railway Industry: Grinding is used for maintaining and manufacturing railway components:

- Railway Wheels and Rails: Grinding is used to reprofile railway wheels and rails, extending their service life and ensuring smooth and safe train operation.

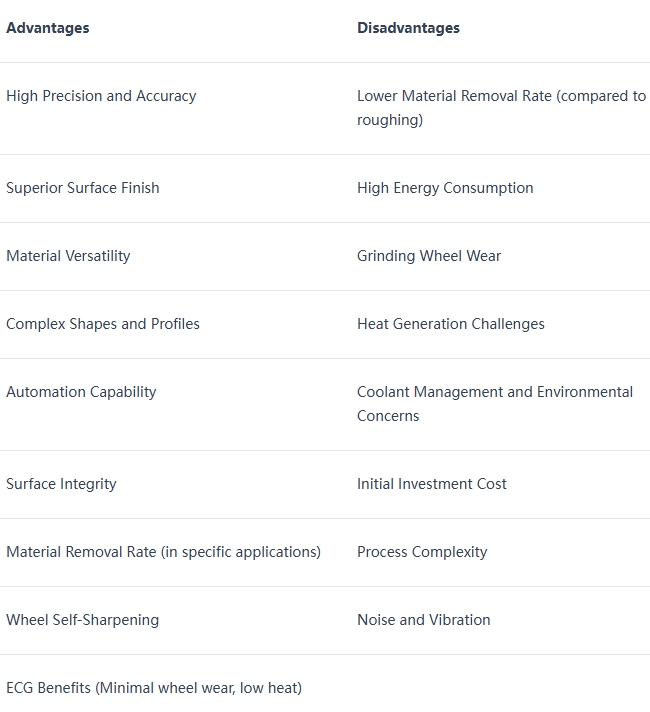

What Are the Advantages and Disadvantages of Grinding?

Grinding offers several significant advantages that make it indispensable in manufacturing, but it also has certain limitations:

Advantages of Grinding:

- High Precision and Accuracy: Grinding can achieve extremely tight tolerances, often in the micron range (± 1-13 µm), making it suitable for precision components.

- Superior Surface Finish: Grinding can produce exceptionally fine surface finishes, ranging from 0.012 µm to 0.8 µm Ra, crucial for components requiring low friction, sealing, or optical quality.

- Material Versatility: Grinding can machine a wide range of materials, including very hard and brittle materials that are difficult to process with other methods.

- Complex Shapes and Profiles: Grinding, especially creep-feed grinding and CNC grinding, can produce intricate shapes and profiles with high accuracy.

- Automation Capability: CNC grinding machines enable automated production, ensuring consistency, reducing labor costs, and increasing throughput.

- Surface Integrity: Grinding, when properly controlled, can minimize surface damage and residual stresses, enhancing component performance and fatigue life.

- Material Removal Rate (in specific applications): Creep-feed grinding and high-speed grinding techniques can achieve high material removal rates in specific applications, competing with milling and turning.

- Wheel Self-Sharpening: The self-sharpening action of grinding wheels maintains cutting efficiency and reduces the need for frequent tool changes.

- Electrochemical Grinding (ECG) Benefits: ECG offers minimal wheel wear, reduced grinding forces, and minimal heat generation, making it ideal for hard and brittle materials.

Disadvantages of Grinding:

- Lower Material Removal Rate (compared to rough machining): In general, grinding has a lower material removal rate compared to rough machining processes like milling or turning, especially for large stock removal.

- High Energy Consumption: Grinding is an energy-intensive process due to high cutting speeds and friction, leading to higher operating costs and environmental impact.

- Grinding Wheel Wear: Although self-sharpening occurs, grinding wheels still wear out and require periodic dressing or replacement, adding to tooling costs.

- Heat Generation Challenges: Grinding generates significant heat, requiring effective coolant systems to prevent thermal damage, distortion, and workpiece burn.

- Coolant Management and Environmental Concerns: Coolant usage in grinding raises environmental concerns related to waste disposal and potential health hazards. Sustainable coolant management practices are increasingly important.

- Initial Investment: Precision CNC grinding machines can have a high initial investment cost.

- Process Complexity: Optimizing grinding parameters for specific materials and applications can be complex and requires expertise.

- Noise and Vibration: Grinding processes can generate significant noise and vibration, requiring noise control measures and machine vibration damping.

Conclusion

Grinding remains a cornerstone of modern manufacturing, providing unparalleled capabilities for achieving precision, surface finish, and dimensional accuracy across a vast range of materials and applications. From automotive and aerospace to medical and tool & die industries, grinding is indispensable for producing critical components that demand high performance and reliability.

While grinding offers numerous advantages, it is essential to acknowledge its limitations, particularly in terms of material removal rate and energy consumption. Ongoing research and development efforts are focused on addressing these challenges and further enhancing grinding technology.

Future trends in grinding technology include:

- Advanced Abrasives: Development of new superabrasive materials and precision-shaped grains to improve grinding efficiency and performance. 3D-printed grinding wheels are also emerging.

- High-Speed and High-Efficiency Grinding: Continued advancements in spindle technology and process optimization to increase material removal rates while maintaining surface integrity.

- Sustainable Grinding Practices: Focus on minimizing coolant usage through techniques like dry grinding and minimum quantity lubrication (MQL), developing eco-friendly coolants, and improving energy efficiency of grinding machines.

- Intelligent Process Monitoring and Control: Integration of advanced sensors, AI, and machine learning for real-time process monitoring, adaptive control, predictive maintenance, and process optimization. Systems like MOPAS, Marposs/Dittel AE monitoring, and Accretech SBS ExactControl™ are examples of advanced monitoring solutions.

- Industry 4.0 Integration: Seamless integration of grinding machines into smart factories through IoT, networked control systems, and data analytics for enhanced automation, flexibility, and efficiency.

- Hybrid Machining Solutions: Combining grinding with additive manufacturing and other machining processes to create more efficient and versatile manufacturing systems.

As manufacturing demands continue to evolve, grinding technology will undoubtedly adapt and innovate, remaining a vital process for achieving precision and quality in the production of advanced components across diverse industries. The integration of digital technologies, sustainable practices, and novel abrasive materials will shape the future of grinding, ensuring its continued relevance and importance in the manufacturing landscape.