Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Spray painting technology applied to battery trays mainly includes two techniques: powder coating (insulating powder) and PVC spraying. Insulating powder coating is primarily used to provide insulation performance for battery trays, and the thickness and uniformity of the coating directly affect the safe operation and protection effect of the battery. PVC spraying, on the other hand, is used to improve the chemical corrosion resistance and weather resistance of the tray, protecting it from environmental erosion and extending its service life. The complementary nature of these two spray painting technologies ensures that battery trays can maintain stable and reliable performance in various complex environments.

In the production and manufacturing project of battery trays for Hesheng New Energy Technology Company, Ctt Technology can provide an integrated one-stop spray painting solution. The same product does not need to go through secondary transportation, and both types of spray painting processes can be completed in the same workshop, thereby helping customers effectively reduce the transportation and labor costs of the box.

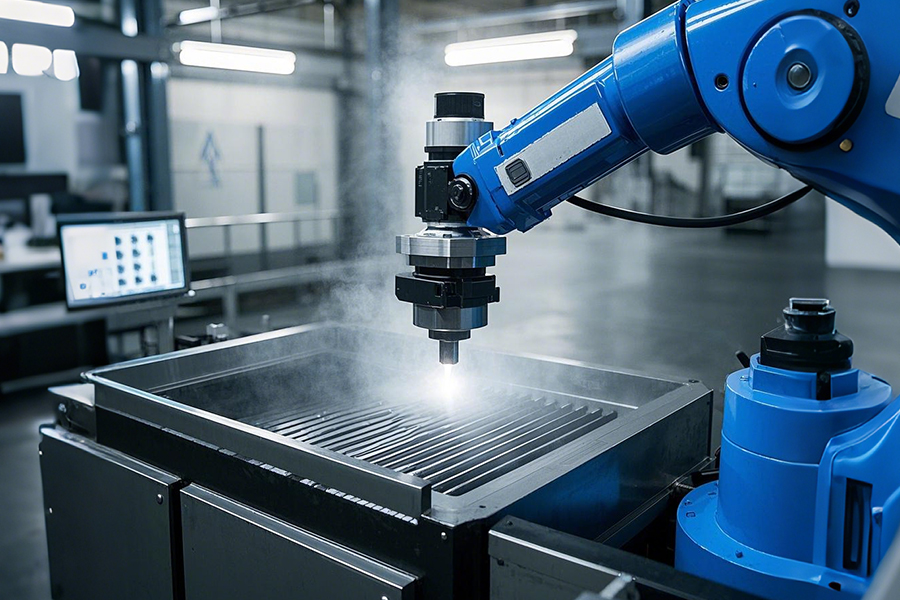

At the same time, we use advanced robotic arm spray painting technology and have established exclusive automatic spray painting lines and tunnel furnaces for our customers, controlling the spray thickness and uniformity at every level to ensure quality control. This automated spray painting method not only helps us achieve a monthly output of 15,000pcs but also significantly shortens the production cycle, with the fastest completion of a perfect spray-painted product in just 12 hours. Through our effective integrated solution, the quality of our customers' products is guaranteed, and material waste is effectively reduced, achieving real cost reduction and efficiency enhancement for our customers.

In the future, CTT Technology will continue to optimize the spray painting process, further improving spray efficiency and product quality through technological innovation and process improvement. We will be committed to developing more environmentally friendly and durable spray painting materials to meet the growing demand for high-performance battery trays in the new energy vehicle industry.

A biological safety cabinet (BSC) provides essential protection for laboratory personnel, samples, and the environment when handling hazardous microorganisms. This article explains BSC functions, material requirements, manufacturing and safety standards, and key testing procedures. It also highlights the differences between biological safety cabinets and laminar flow hoods, helping users select the proper equipment for their laboratory. Through clear guidance on certification and maintenance, the article supports safer, more efficient laboratory operations.

Learn the importance of inkjet printer shell design, including material selection, structural requirements, manufacturing processes, maintenance methods, and solutions for common shell failures. Improve durability, stability, heat dissipation, and overall performance of industrial inkjet printers with expert guidance.

This article analyzes the advantages of laser cutting technology in sheet metal welding processing, including high precision, rapid cutting, and reduced material waste. Through practical examples, it demonstrates the significant effects of laser cutting in improving production efficiency and reducing costs, and discusses future technological development trends.

Sheet metal processing is essential in bus chassis manufacturing, significantly improving the chassis's strength, stability, and safety. Through technologies such as laser cutting, stamping, and welding, manufacturers can improve production efficiency while ensuring chassis quality. With the advancement of intelligent manufacturing and green production, the future of sheet metal processing will be full of more innovative opportunities.

Email to this supplier

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.